Nyefee igwe anaghị agba nchara electrodes aws e308 e308l

Njirimara na ngwa

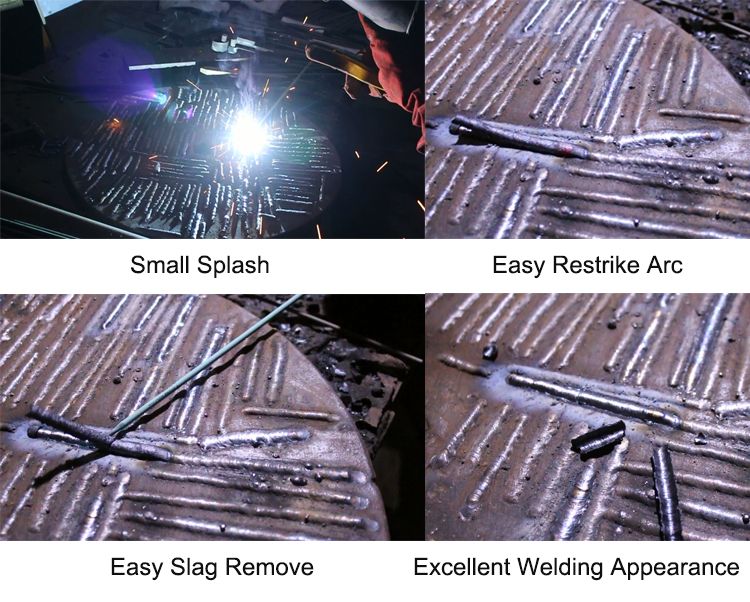

TheweldmetalofE308/308Lisa19Cr-10Ni austenite microstructure nke nwere oke ferrite.Ntọhapụ inslag dị mma, ọdịdị bead weld, weldability, corrosion resistibility na elu okpomọkụ bụ ihe niile ga-enweta.Ọ dabara maka ịgbado ọkụ nke AlS1-304 ígwè, AlSI-301 ígwè na AISI-302 ígwè na niile ọnọdụ.

Kwesịrị ekwesị isi metalforE308/308L: igwe anaghị agba nchara, hoop, ọkpọkọ, enweghị nkebi ọkpọkọ, thermal ọkpọkọ, mgbali arịa efere, ígwè mmanya, forge.

Ihe ndetu maka ojiji

1.Clean up the conteminations on the base metal groove wee gafee na igwe anaghị agba nchara ahịhịa.

2.Maintaining mkpụmkpụ arclength dị ka o kwere mee na-atụ aro nke ukwuu.Mgbe ị na-eji usoro akwa agbado, a ga-achịkwa oke mbugharị n'ime oge 2.5 nke dia waya.

3. Ghichaa electrodes na 250 ~ 300 ℃ maka nkeji 60 tupu ojiji.Wepụ consumables maka ọkara ụbọchị oriri na-na-na gburugburu ebe obibi na 100 ~ 150 ℃ n'oge ịgbado ọkụ usoro.

4.Jiri obere ugbu a iji gbochie ịgbawa ma belata dilution metal base.

Nkọwa

| Nlereanya | GB | AWS | Dayameta (mm) | Ụdị mkpuchi | Ugbu a | Na-eji |

| CB-A102 | E308-16 | E308-16 | 2.5-5.0 | Ụdị lime-titania | DC | Ejiri ya maka ịgbado ọkụ corrosion-eguzogide0cR19Ni9 na 0Cr19Ni11Ti igwe anaghị agba nchara n'okpuru 300︒C |

Ngwakọta kemịkalụ nke ọla edobere (%)

| C | Mn | Si | S | P | Cr | Ni |

| ≤0.02 | 0.85 | 0.70 | 0,030 | 0.010 | 19.3 | 9.5 |

Njirimara Mechanical nke ọla edobere

| Ike Tensile (Mpa) | Mgbatị(%) |

| 570 | 45 |

Nkwakọ ngwaahịa

Ụlọ ọrụ anyị

Ihe ngosi

Asambodo anyi