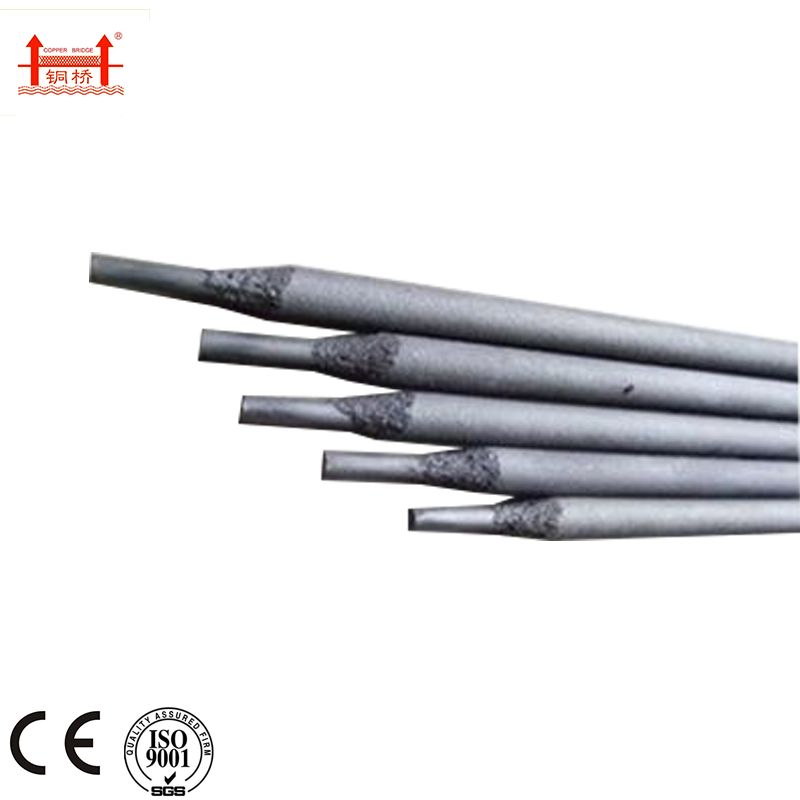

Igwe anaghị agba nchara Electrodes CB-A102

Igwe anaghị agba nchara na-eji ọkwa

1. chromium igwe anaghị agba nchara nwere ụfọdụ corrosion eguzogide (oxidizing acid, organic acid, cavitation) , okpomọkụ na-eguzogide na eyi iguzogide.A na-ejikarị ya na ụlọ ọrụ ọkụ, kemịkalụ, mmanụ ala na akụrụngwa ndị ọzọ.Chromium igwe anaghị agba nchara weldability adịghị mma, kwesịrị ịṅa ntị na usoro ịgbado ọkụ, ọnọdụ ọgwụgwọ okpomọkụ na nhọrọ nke electrode kwesịrị ekwesị.

2. CR-13 igwe anaghị agba nchara nwere ike dị elu mgbe ịgbado ọkụ ma dị mfe ịmepụta mgbape.Ọ bụrụ na a na-eji otu ụdị chromium igwe anaghị agba nchara (G202, G207) maka ịgbado ọkụ, a ga-ekpocharịrị ya n'elu 300 Celsius C ma mee ka ọ dị jụụ ihe dịka 700 Celsius C mgbe ịgbado ọkụ.Ọ bụrụ na ịgbado ọkụ enweghị ike rụrụ post-weld okpomọkụ ọgwụgwọ, mgbe ahụ, nhọrọ nke chromium-nickel igwe anaghị agba nchara electrode (A107, A207).

3. Chromium 17 igwe anaghị agba nchara, iji mee ka nguzogide corrosion na weldability dịkwuo mma ma mee ka ihe nkwụnye kwesịrị ekwesị dị ka Ti, Nb, Mo, wdg, weldability dị mma karịa chromium 13 igwe anaghị agba nchara.Mgbe a na-eji otu ụdị chromium igwe anaghị agba nchara (G302, G307) eme ihe, a ga-ekpocha ya ọkụ n'elu 200 Celsius C ma mee ka ọ dị ọkụ gburugburu 800 Celsius C mgbe ịgbado ọkụ.Ọ bụrụ na ịgbado ọkụ enweghị ike ikpo ọkụ, mgbe ahụ, nhọrọ nke chromium-nickel igwe anaghị agba nchara electrode (A107, A207).Igwe anaghị agba nchara CR-NI nwere ezigbo nguzogide corrosion na nguzogide oxidation, nke a na-ejikarị eme ihe na ụlọ ọrụ kemịkalụ, fatịlaịza, mmanụ ala, nrụpụta akụrụngwa ọgwụ.

4. 0 na n'okpuru nwere ike ji mee ihe niile-ọnọdụ ịgbado ọkụ.

5.0 na n'elu maka ịgbado ọkụ dị larịị na ịgbado ọkụ fillet.

6. Chromium-nickel igwe anaghị agba nchara nwere ụdị titanium-calcium na ụdị hydrogen dị ala.Calcium titanate ụdị nwere ike iji na AC na DC, ma penetration nke-emighị emi AC ịgbado ọkụ, mgbe mfe na-acha uhie uhie, ka iji DC ike ọkọnọ.Dayameta

7. Ekwesịrị idobe electrode akọrọ, ụdị titanium-calcium kwesịrị akpọnwụ na 150 Celsius C maka awa 1, na ụdị hydrogen dị ala kwesịrị akpọnwụ na 200 ° C ruo 250 Celsius C maka awa 1 (ọ dịghị ihicha ugboro ugboro, ma ọ bụghị ya). mkpuchi ahụ dị mfe ịgbawa ma kpochapụ) , gbochie mkpuchi electrode na-arapara mmanụ na unyi ndị ọzọ, ka ọ ghara ịbawanye ọdịnaya carbon nke weld na-emetụta àgwà nke ịgbado ọkụ.

8. Iji gbochie corrosion n'etiti anya nke kpo oku na-akpata, ịgbado ọkụ ugbu a ekwesịghị ịbụ oke ibu, ihe na-erughị carbon ígwè electrode banyere 20% , ARC ekwesịghị ịdị ogologo, ngwa ngwa jụrụ n'etiti n'ígwé, ka warara bead kwesịrị ekwesị. .

| Nlereanya | GB | AWS | Dayameta (mm) | Ụdị mkpuchi | Ugbu a | Na-eji |

| CB-A102 | E308-16 | E308-16 | 2.5-5.0 | Ụdị lime-titania | DC | Eji maka ịgbado ọkụ corrosion 0cR19Ni9 na 0Cr19Ni11Ti igwe anaghị agba nchara n'okpuru 300︒C |

Ngwakọta kemịkalụ nke ọla edobere

| Ngwakọta kemịkalụ nke ọla edobere (%) | ||||||||

| C | Mn | Si | S | P | Cu | Ni | Mo | Cr |

| ≤0.08 | 0.5-2.5 | ≤0.90 | ≤0.030 | ≤0.040 | ≤0.75 | 9.0-11.0 | ≤0.75 | 18.0-21.0 |

Njirimara Mechanical nke ọla edobere

| Njirimara Mechanical nke ọla edobere | |

| Rm(Mpa) | A(%) |

| ≥550 | ≥35 |

Nkwakọ ngwaahịa

Ụlọ ọrụ anyị

Ihe ngosi

Asambodo anyi